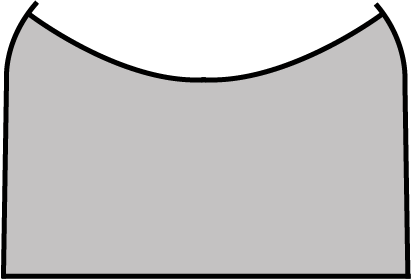

Have your tablets ever looked like this after running your formulation through the machine: Capping (left) and lamination (right) are fracture defects in tablets that happen during compression and ejection in tablet pressing.

Similar to capping, lamination happens when the body, rather than the top, of a tablet is fractured into horizontal layers.

Time and product are wasted when tablets come out broken and cracked, and it’s important to investigate to find out the source of what is causing the defect so production can get back in business. It could be as simple as looking at the punches of the tablet press machine for wear patterns. Do you know where to begin?

Let’s start by becoming familiar with the different parts of tooling that focus on the punch parts that are directly involved with tip wear and tablet defects.

Working Length - The working length of the punch is from the very top of the head flat to the lowest measurable area of the cup depth. This is the most crucial area when inspecting your tooling, because it leads to consistent hardness, weight, and thickness in your tablets. The lower punch’s working length is important because it controls the product fill and doses in the die.

Cup Depth and Land - Another vital part of your punch is the cup depth. The cup depth makes the appearance of your tablet’s face. The land is the flat area around the punch’s cup. As your punch’s wall or land wears down, it will decrease the cup depth and change the characteristics of your tablet.

Overall Length – The overall length of a punch is the distance from the head to the highest part on the land—in other words, it is the working length and cup depth measurements combined. It can also be important to setting punch height for tablet uniformity and preventing tablet damage.

The land is usually the first part of the punch to wear, which may lead to the formation of a J-hook. So, what is a J-hook on a punch and why does it affect your tablet quality?

A J-hook is a mark of wear on a tablet press punch. The edge of the punch tip curls inward, which reduces the cup depth:

Look for a J-hook on your punch by running your finger in the inner edge of the cup and feeling for a curved edge.

What to do if you find a J-hook on your punch

J-hooks are a relatively simple fix—the burr needs to be removed and the punch's land needs to be refurbished by a trained technician. The technician needs to polish the punch with an unsewn buff wheel (don’t use a drag finisher because it can't restore the land). If there is severe wear, the technician can use a 400-600 grit stone and then buff the punch. If this doesn’t work, all of the tooling (upper punch[es], lower punch[es], and die[s]) needs to be replaced.

What causes J-hooks and wear on punches? Can it be prevented?

Although wear can naturally happen in tablet press tooling, there are a number of reasons as to why severe cases, such as J-hooks, form on a punch. The reasons can range from tooling design, improper tooling or other tablet press parts installation, or incompatible formulation characteristics.

Here is a short list below of common causes of tooling wear and what to do about it:

It’s not just part of best practices to inspect your machine parts, including the punches and dies, before, during, and after operation, but it can save you from the frustration that comes with trying to figure out why your tablets are breaking. Broken tablets aren’t only aggravating but also costly, with you losing time and money because of them. Quality punches and dies are essential in ensuring that your tablet-making efforts are successful, and implementing monitoring them into your maintenance procedures ensures you’ll be manufacturing your own product with no interruptions.

Wear in your tablet press tooling slowing down your production? Contact our sales team today to learn more about our diverse assortment of punches and dies by emailing sales.usa@lfamachines.com. We also have several resources for you to help with good tooling maintenance practice and how to take care of your punches and dies– check out more of our articles as well as our videos on our website.